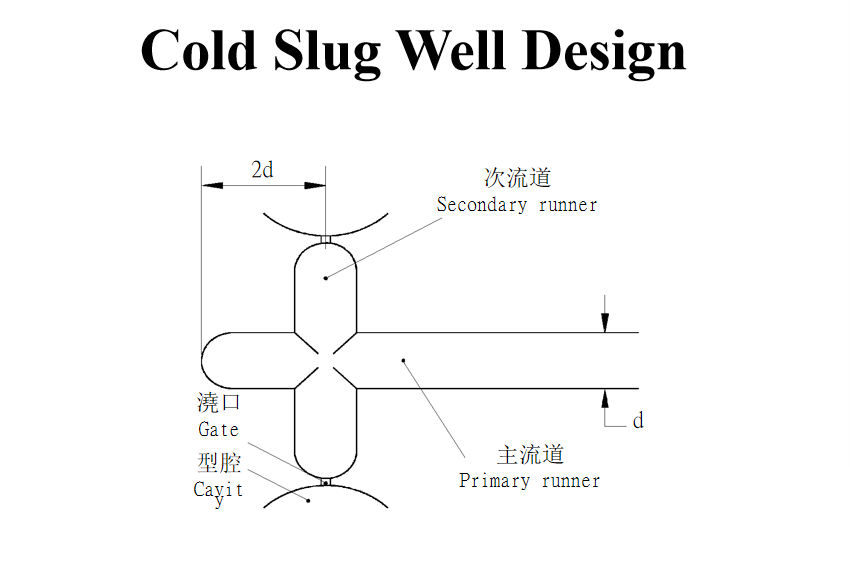

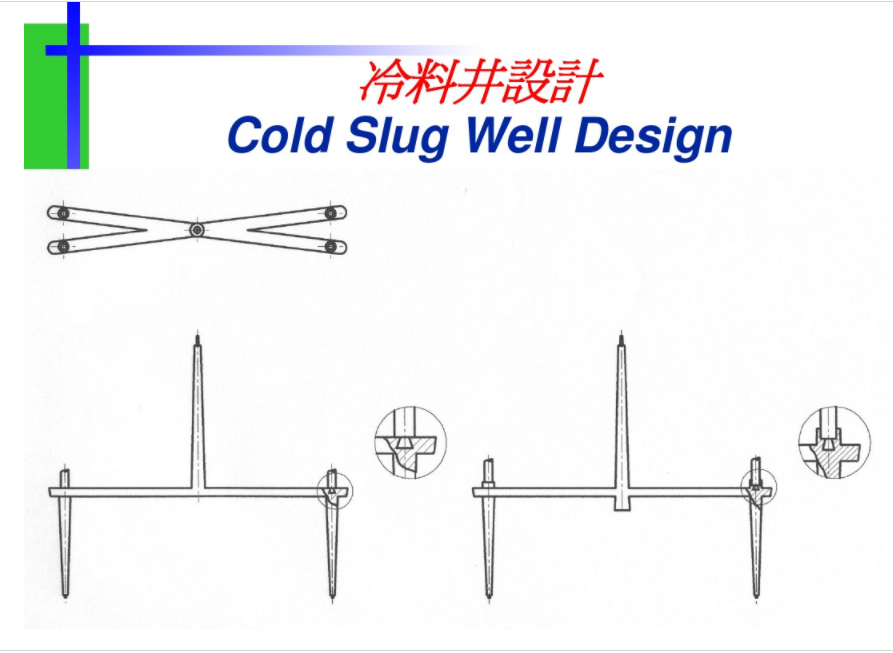

Cold slug well is a very imporant part of plastic mold design. It is defined as the small nub of plastic that cools and solidifies inside the nozzle tip during the cooling cooling phase of the injection cycle. It is designed to store cold slug caused intermittently by the nozzle due to heat loss and low temperature. Cold slugs could clog or slow down the material flow in runner and cavity and cause cold scars or cold marks on plastic part. The cold slug well is usually placed at the end of primary runner. When the branch runner is too long, cold slug well should be designed as well to store the front plastic cooled by mold.

Cold slug well is a very imporant part of gate system and it should not be neglected at mold design.

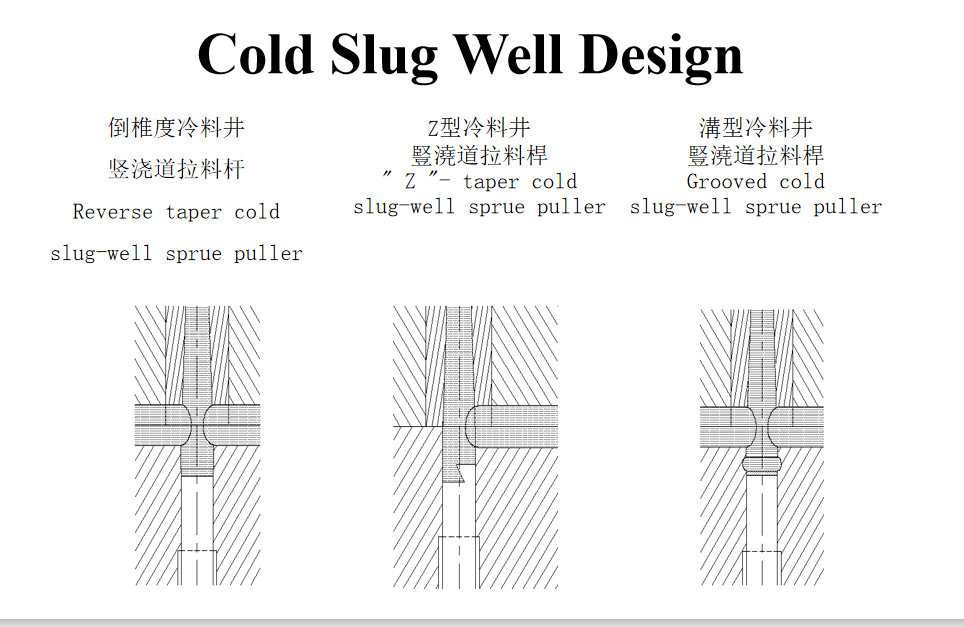

For molded plastic part made from flame-retardant PC, the design of cold well determines the the quality of injection molding parts. In order to achieve the corresponding fire resistance grade, a large number of flame retardants have to be added to the PC ,where the proportion of flame retardants is even 20%, so the processing temperature of the flame retardant PC cannot be set very high.Normal processing temperature of the PC is 320°C, but the processing temperature of the flame retardant PC is generally 270~290°C, and some PC can even be processed at 240~250°C. If the flow of the PC cannot be increased by raising the temperature, the runner design of the plastic mould needs to be more reasonable. Especially the design of cold wells, the diameter should be slightly thicker than the main channel, and it is slowly thickened. Besides, there should be reverse hook to prevent the cold plastic slug in the well from being washed into the molding parts again because of the high pressure of the plastic fluid. It is also important to note that the corner of the channel is prone to cause stress concentration and round corner should be designed as large as possible.

Español

Español