Plastic injection mold is the foundation of the success of

custom plastic part and we mainly discuss the design basics you need to know when developing your plastic project in this series of articles.

Designing plastic injection mold for manufacturability is the first step in making a high-quality part.

Before start, we need to understand what is the standard of a well-designed mold.

- The basic function of a mold is two fold.

- Firstly it should impart shape to the part

- secondly it should cool the molded part.

- The number of cavities mainly depends up on the production volume requirement. But it is also related to the size and weight of the parts which in turn determines the machine capacity required.

- It is also important to design a mold that will safely absorb the forces of clamping, injection and ejection.

Further more the mold lay out should be balanced which will ensure proper filling and dimensional control.

Secondly, DECIDING THE TYPE OF MOLD

Secondly, DECIDING THE TYPE OF MOLD

There are several types of injection molds in use today.

- Two plate.

- Multi plate mold.

- Hot runner mold

- Insulated hot runner mold

- Hot runner manifold

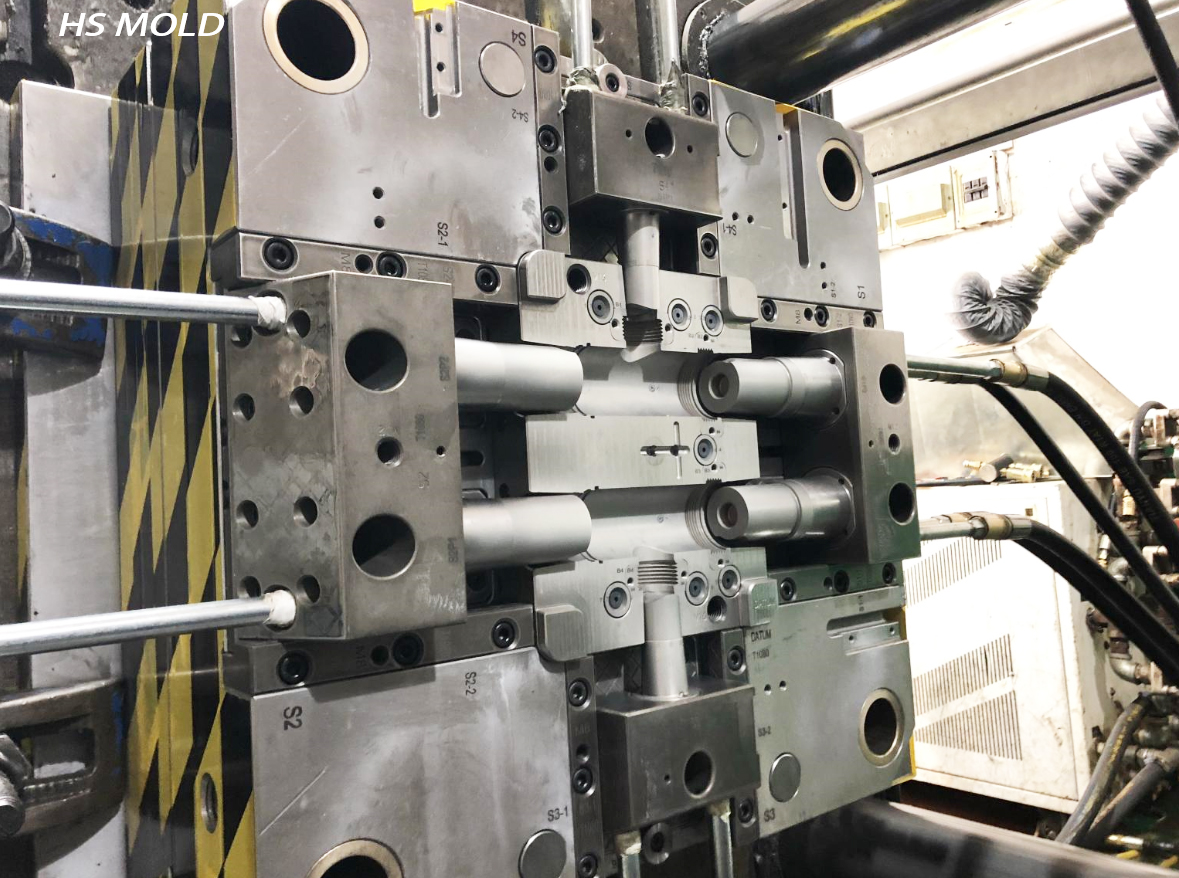

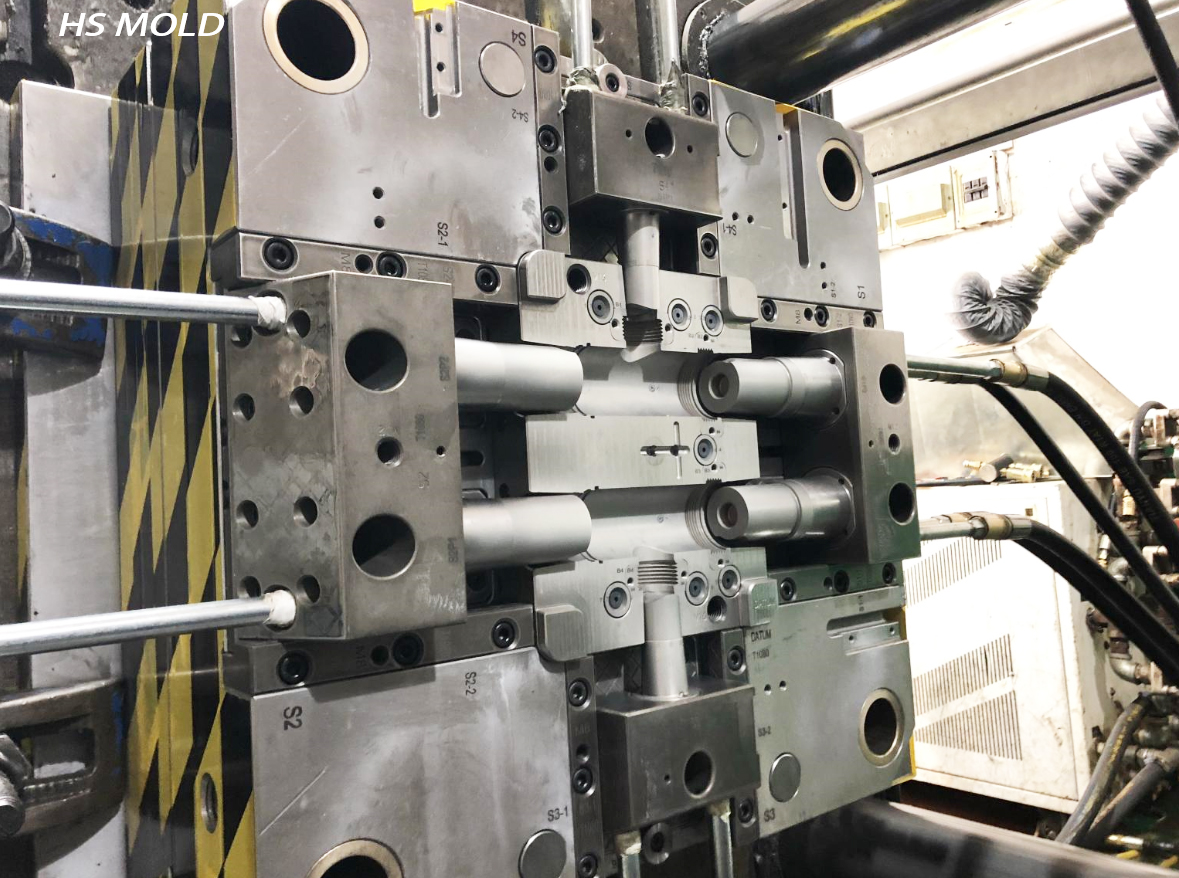

- stack mold

A

two plate mold has got only single day light (one opening). All basic designs of injection molds have this design thought. A two plate mold is the most reasonable type of tool to use for part requiring large gates.

A

multi plate mold has got more than one day light. In this design it is possible to separate the runner system and the part as the mold opens. Multi cavity with back feeding is also possible.

In a

hot runner mold the runners are always kept in molten state. There is no runner wastage and no gate vestige. The cycle time is less and uniform temperature can be maintained and hence uniform properties.

The

insulated hot runner is a variation of hot runner mold. In this type runner the outer surfaces act like an insulator for the molten inside material. In the insulated runner the material inside remains molten by retaining its own heat.

Some times a torpedo or a hot probe is added for flexibility. This type of runner is suitable for multi cavity centre gated parts. The size of the runner is almost twice the diameter when compared to the cold runner system.

The hot – manifold is a variation of the hot runner mold. In the hot runner mold the runner plate is heated where as in the hot runner manifold mold the runner, sprue, gate etc are heated by inserting cartridge heaters inside them.

A

stack mold is multiple two plate mold with the molds one placed on top of the other. This construction also can be used with three plates, hot runner, and insulated runner molds. A stacked two mold construction doubles the production from a single machine. The machine will require additional shot capacity.

Thirdly, EVALUATING THE DESIGN OF THE PART

The design of the component firstly depends upon the intended use and secondly the limitation of the injection molding process. The properties of the plastic material and the engineering aspects of the mold construction are the additional factors.

Curved, grooved or uneven surfaces are preferred than flat surface. Flat surfaces always warp after molding.

This warping can be prevented by providing ribs but rib can cause sink marks. All the corners should be rounded to prevent the chance of cracking and also to increase flow.

The thickness of the part should be kept minimum and as uniform as possible. This will make sure,

- Minimum material usage less cycle time

- uniform shrinkage

- uniform filling of part and Less chance of internal stress

Lastly, Injectin Mold Design Guide

One of the important decisions required while designing is how to retain the part on the side where you have planned ejection.

he part during opening can be retained on the required half by applying the following methods.

- Relying on the shrinkage of the molding.

- BY modifying the parting line.

- By providing under cut.

- By reducing or increasing the draft.

- By varying the surface finish.

- By using side core.

- BY using lifters.

- By using push pins.

- By using air puppets.

- By modifying the design.

HS Mold engineering team has worked out basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time. Contact us for more technical detailes!

Secondly, DECIDING THE TYPE OF MOLD

There are several types of injection molds in use today.

Secondly, DECIDING THE TYPE OF MOLD

There are several types of injection molds in use today.

Español

Español