Plastic Injection Mold Maker

HS Mold is an injection mold manufacturer in china. Since 2004, it offer plastic injection molding services to plastic injection molding companies.

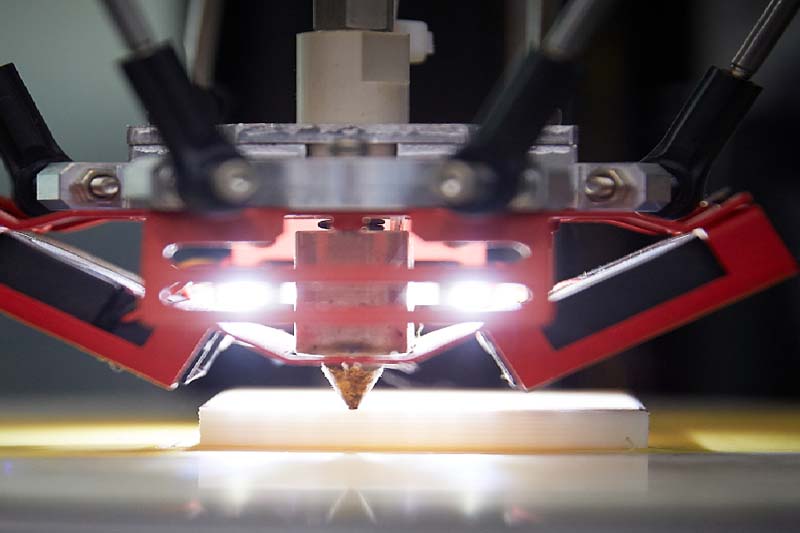

Custom Plastic Injection Molding Service

Get custom plastic parts within days.

Request an online quote.

We Makes Plastic Molds for Efficiency, Longevity and Performance in China

HIGH PRODUCTION VOLUME

SHORT LEAD TIME.

Español

Español