This article discusses basic consideration for designing two-shot injection molds, which is referred to also as dual-shot, dual-injection, double-shot, double-injection, multi-shot, 2k molding, and overmolding

- Before tool design, one should check machine injection unit Injection unit sometimes constrain the tooling type.

- Material shrinkages for each material should be considered. Shrinkage may cause warpage and flash if those are not made up properly in tooling phase.

- If there is big different in melt temperature between materials, toolheat balancing should be .studied

- Tooling should consider gate location, access, allowable gate vestige.

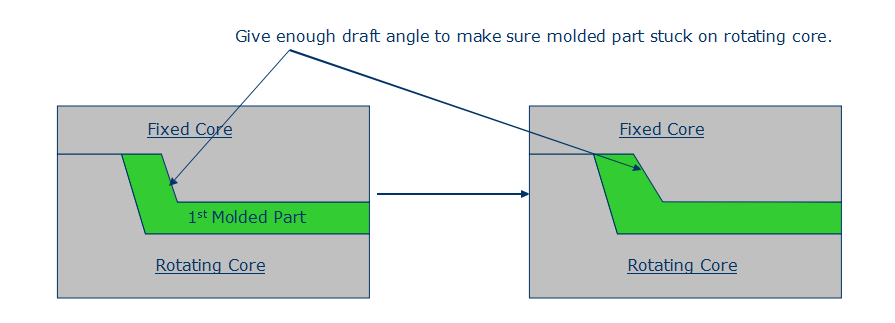

- Draft angle in 2K molding is very critical factor which deciding wheremolded part stuck and rotating. In 1st shot molding, molded part should be stuck on rotating core and 2nd shot molding, molded part should remain on the side of ejecting system employed.

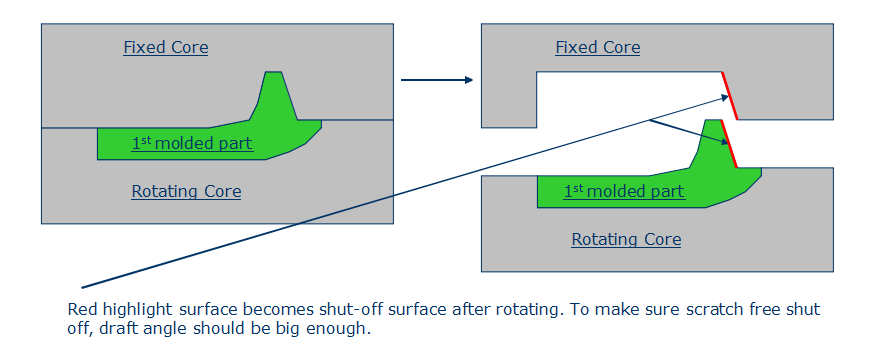

- If part design imposing creating shut-off surface with molded part after rotating,Draft angle on shut-off surface should be big enough not tomake scratch issue when tool closed for 2nd shot.

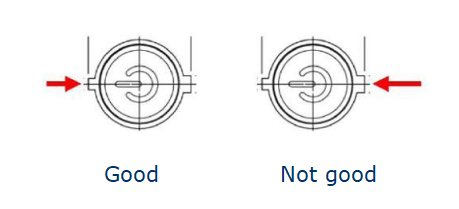

2nd shot Gate

- As big as possible. Fan gate is prefered

- At thickest section

- Try to havea shortest flow length

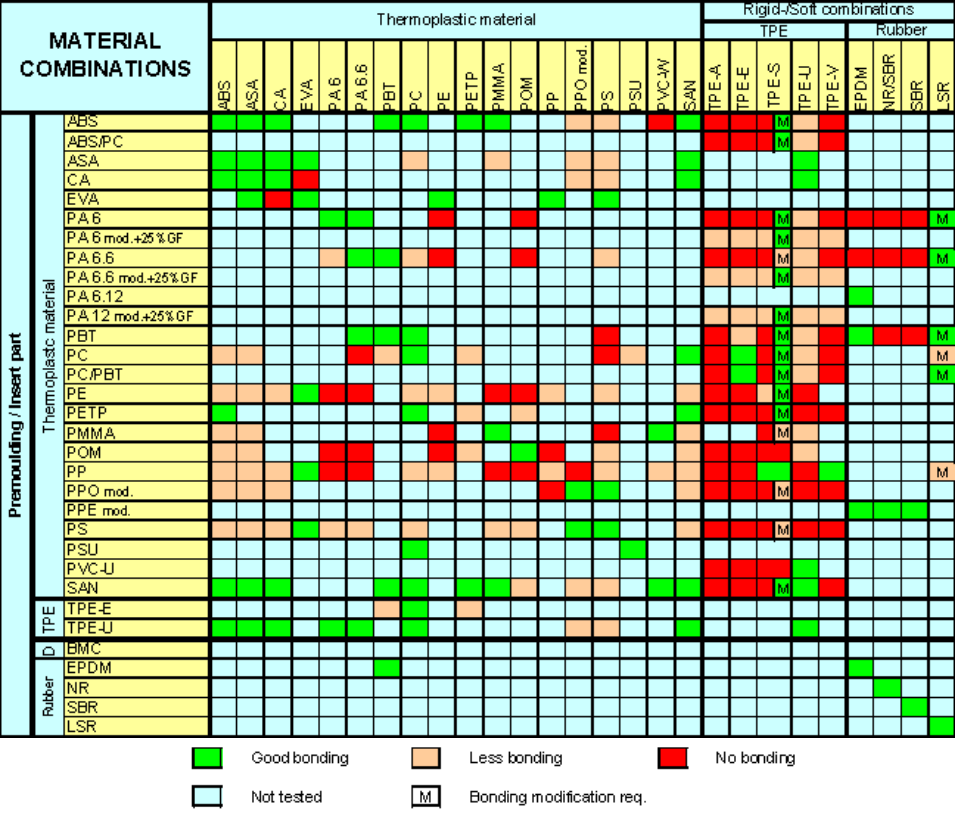

In material selection process, Mostly the critical elements must be met are application performance and adhesion between molded materials. For those reasons, following principles in selection phase are recommended.

§ Select materials which have CTE as same as possible.

- Select materials which have shrinkage rate as same as possible.

- Select chemically similar resins

- Avoid the combination of amorphous and crystalline materials

Another factor must be considered is the sequence of molding material, Material sequence have to set as what is more important that others

§ To enhance adhesion- generally been found that injection of the higher temperature material second produces better adhesion.

- To prevent “Wash-out” & “Winkle”, Higher HDT material shouldbe shot first.

- lower viscosity material for 2nd shot is very helpful to prevent “Wash-out”.

- Always to shot transparent layer first to minize“wash-out”.

With decades of experience in manufacturing double injection moulds, we know that tooling design is a key to reduce cost and and improve quality for your part. Above tooling considerations should be kept in mind at two-shot design process. This is the key to the success of two shot injection molding project.

Español

Español