Custom Product Manufacturing

Start-to-Finish Custom Product Manufacturing

HS Mold: Your One-Stop Solution for Custom Product Manufacturing Challenges. From plastic to metal parts, we streamline your project, saving you time and money by consolidating everything under a single roof. Our expertise shines in managing short-term and complex tailored projects, catering to demanding customers worldwide

Get an Instant Quote

With our core competency in mold making and custom injectoin molding, we could provide one stop contract manufacturing service including design, prototying solution, purchasing, assembly, small batch injection molding, long run injection molding, complex assembly, secondary operations, testing, packaging and shipping.

Our Custom Product Manufacturing experience spans a wide range of industries for domestic and global OEMs, including medical/healthcare, industrial,agricultural, lawn and garden, appliances, consumer products and powersportssuch as marine and recreational and utility vehicle.

Starting a new venture or managing an existing one, you’ve likely felt the frustrations that come with Custom Product Manufacturing. We understand the pains that startups, engineers, and purchasers often face in their quest for reliable custom product manufacturing solutions. That’s where we step in, armed with expertise and a commitment to make your journey smooth and stress-free.

Lack of Expertise

You’re brimming with ideas, but technical intricacies can be overwhelming. Our core competency in mold making and custom injection molding means we’re fluent in the language of Custom Product Manufacturing. No more puzzling over designs or processes – we bridge the knowledge gap.

Limited Resources

Budget constraints can dampen your plans. We specialize in cost-effective process selection. Our experience lets us choose the right manufacturing process to balance quality and affordability. You’ll get remarkable products without breaking the bank

Communication Challenges

Time zones and language barriers shouldn’t hinder progress. Our seamless communication ensures that ideas are translated flawlessly into products. Say goodbye to misunderstandings that delay projects.

Minimum Order Requirements

Start small, dream big – that’s your motto. Our no-MOQ policy echoes this sentiment. Whether you need one prototype or a handful, we’re here to support your journey without demanding high minimum orders

Unpredictable Timelines

In the fast-paced business world, time is money. Our streamlined processes and punctual production cycles ensure your projects stay on track. No more missed market windows or frustrating delays.

Intellectual Property Protection

Your innovations deserve protection. We value your intellectual property and take every measure to safeguard your designs and proprietary information.

Supplier Reliability

Dependable partners are crucial. With over 1000 successful cases, our track record speaks volumes. You can trust us to keep your supply chain running smoothly.

Sourcing Complexities

Material sourcing can be daunting. Our strategic location in Dongguan, the heart of global manufacturing, grants us unparalleled access to materials and parts, relieving you of sourcing burdens.

Hidden Costs

Surprises belong in celebrations, not in manufacturing budgets. Our transparent approach ensures that you’re aware of all costs upfront, eliminating unexpected financial strain

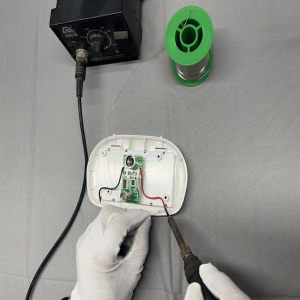

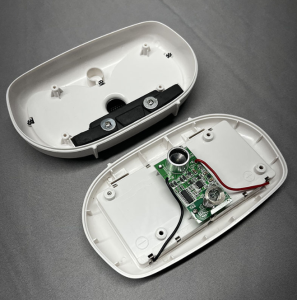

HS Mold offers a wide range of assembly services for Custom Product Manufacturing. Some of the most common assembly processes we perform for our global clients include:

- Mounting metal parts

- Drilling and tapping holes

- Assemble threaded inserts

- Adding Teflon tape to threads

- Secondary finish operations such as paiting, printing,chrome plating, powder coating, etching and ect.

- Boxing and/or other packaging

Over the years, we have completed more than 500 projects requiring assembly service for clients across the globe. It’s always easier to deal with a partner where all of these disciplines are run by a single company rather than having to communicate with multiple companies.

We provide full manufacturing service for your project, from prototyping solutions to assembly and final packaging. Contact us to learn more!

1. What is your company’s core competency?

Our core competency lies in mold making and custom injection molding. We specialize in providing comprehensive contract manufacturing services that encompass design, prototyping solutions, purchasing, assembly, small and large batch injection molding, complex assembly, secondary operations, testing, packaging, and shipping.

2. What industries do you serve with your custom product manufacturing services?

We have extensive experience serving a diverse range of industries, both domestically and globally. Our expertise extends to sectors such as medical/healthcare, industrial, agricultural, lawn and garden, appliances, consumer products, and powersports. This includes marine and recreational products, as well as utility vehicles.

3. What is the scope of your manufacturing capabilities?

Our manufacturing capabilities cover the entire process, from initial design and prototyping to assembly, testing, and shipping. We handle small batch injection molding as well as long run injection molding. Our services also include complex assembly, secondary operations, and various testing procedures to ensure the quality of the final product.

4. Can you provide more information about your design and prototyping solutions?

Absolutely. We offer comprehensive design and prototyping solutions tailored to each client’s specific needs. Our skilled team collaborates closely with clients to bring their concepts to life, utilizing advanced design software and cutting-edge prototyping techniques.

5. How do you ensure the quality of the manufactured products?

Quality is our top priority. We implement rigorous quality control measures throughout the manufacturing process. Our team conducts thorough testing and inspection of the products to ensure they meet the highest standards before they are packaged and shipped.

6. What batch sizes do you accommodate for injection molding?

We are equipped to handle a wide range of batch sizes, from small to large runs. Whether you require a limited production run or a high-volume manufacturing process, we have the capabilities to meet your needs efficiently.

7. Do you offer specialized services such as secondary operations?

Yes, we do. In addition to our injection molding services, we offer secondary operations that can include various finishing processes, assembly of intricate components, and additional treatments to enhance the functionality and appearance of the final product.

8. How can I request a quote for my custom manufacturing project?

Getting a quote is easy. Simply reach out to our team through the contact information provided on our website. We’ll be happy to discuss your project requirements, provide a detailed quote, and answer any questions you may have.

9. Can you manage global shipping for the manufactured products?

Absolutely. We offer end-to-end solutions, including packaging and global shipping. Our logistics experts ensure that your products are delivered safely and efficiently to their intended destinations.

10. How can I learn more about your past projects and client success stories?

You can explore our website’s portfolio section to learn more about the diverse range of projects we’ve successfully completed for various clients. These case studies highlight our capabilities and the positive outcomes we’ve achieved.

Español

Español