– MANUFACTURING SERVICE

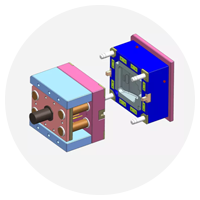

Tooling

We builld molds for Efficiency, Longevity and Performance.Whatever your need, rapid prototype tooling, low volume tooling, production tooling or export tooling, we could support you with most comprehensive mold making capacities.

Get an instant quote

Español

Español