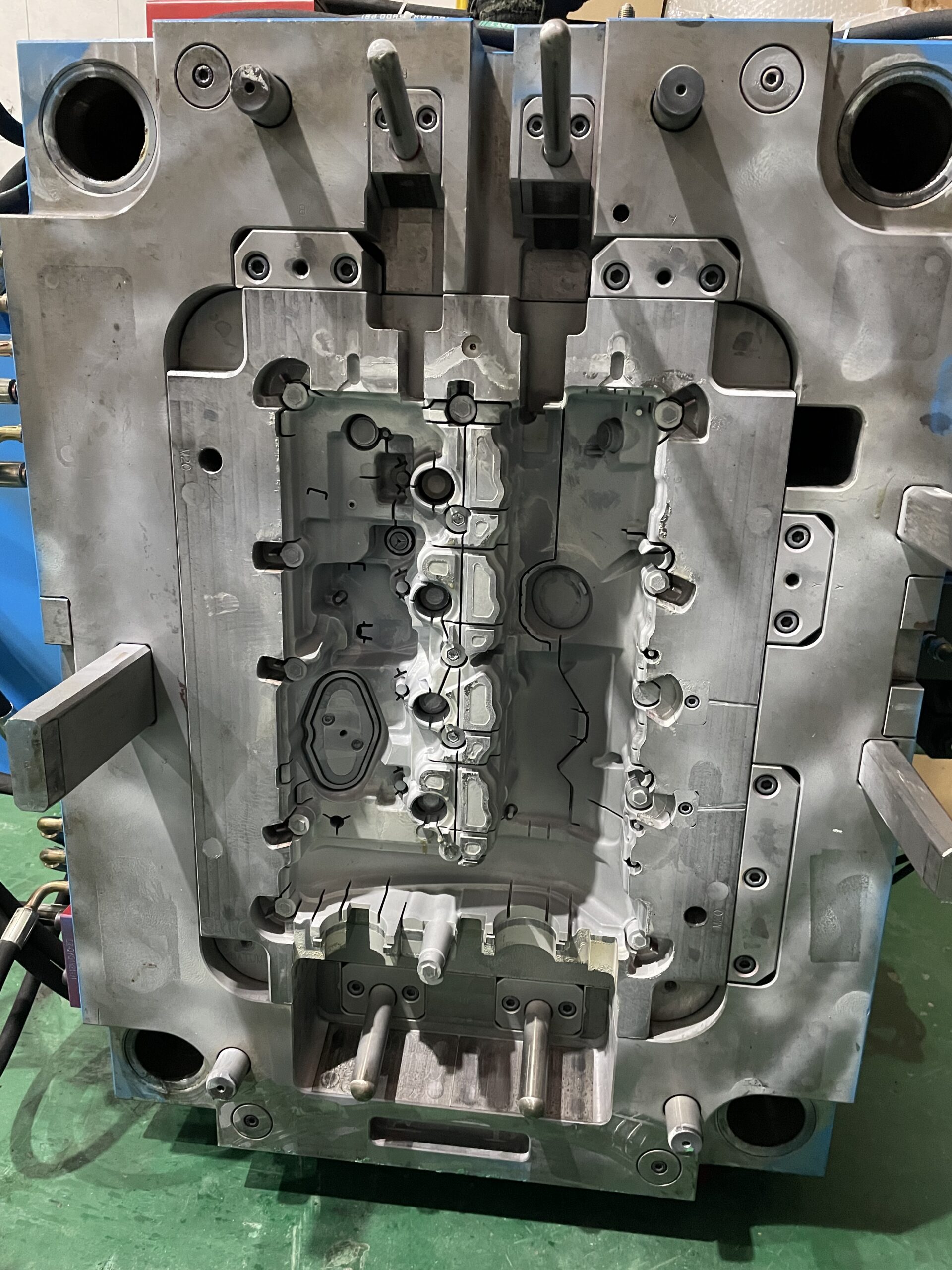

Automotive Injection Mold

Why Automotive Injection Mold for Engine Cover

The market is driven by regulatory demands for lower CO₂ emissions. Therefore, we help client to develop and manufacture this Automotive Injection Mold for Engine Cover. We change the material from steel to engineering plastics. Weight is reduced and cost saved up to 60 % in comparison to steel without compromising strength. In this case, plastic provides greater opportunity to manufacture parts that can be molded into complex shapes at a much lower cost than machining metal components.

Mechanism of the Automotive Injection Mold

This is a very complex tooling. Material is Nylon filled with 35% Fiber Glass. Plastic components made from this material are often superior when it comes to high-impact strength, fatigue life or recoverable deformation. Besides, the plastic engine cover provides better wear surfaces and having lower friction.

This is the plastic housing for automotive engine. It is usually made of aluminium, but automotive companies are now using plastic as replacement to save cost and energy.

- Material is Nylon+35%GF.

- The mechanism of the plastic injection mold is quite complex with 11 lifters on cavity and 4 lifters on the core.

- Firstly, as know, the part bottom needs to be quite flat without any warp,otherwise the oil may leak.

- Secondly, there are 16 locating holes around the parts, and each of them contracts towards different direction irregularly and the position of the holes move during the molding process. In this case, we have to make all holes as inserts and note down the molding parameter. After trial, we measure the actual position and make new inserts. This process has to be repeated until the holes fit with the assembly metal parts. It is insert injection molding process.

- The big hole on the middle is the most complicate part. It features with double oblique holes. One angle slide drives 4 lifters.

- The plastic mold size is 650x880x900mm with the weight of 4000KG.

Our Capability of manufacturing Automotive Injection Mold

We are one of the profesional plastic injection mold manufacturers in China. Our engineering team are capable of introducing and improving engineered plastic resins that have the strength and durability to compete with metal. The market’s future is moving electric automotive lightweighting.We support automotive and industrial manufacturers to produce re-invented technology for optimized use.

And we have been engaged in injection mold making and custom injection molding in China over 20 years. If you are looking for high quality injection mold China, you are welcome to contact us to have the detail of the mechanism.

As a most experienced plastic mold maker in China, we also make complex Automotive Injection Mold for other intricate automotive parts such as Coolant Radiator and reservoir cap. There are thousands of China Mold Manufacturer, only those like HS that equiped with most advanced mold making technology could handle your complex work.

Contact us today to see how we could benefit your next Automotive Injection Mold project!

Español

Español