The Advantages of CNC Machined Aluminum for Prototypes:

- Unmatched Precision and Repeatability:CNC (Computer Numerical Control) machining utilizes precise computer programs to control cutting tools, achieving tolerances up to ±0.005 inches. This ensures your prototypes function flawlessly, matching your design intent exactly. Additionally, CNC machining guarantees consistent quality across every prototype, minimizing the risk of defects. (Consider adding “CNC machining aluminum for prototypes” here for keyword density)

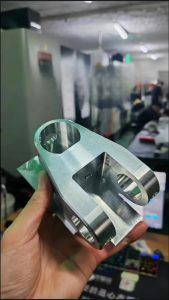

- Design Freedom Unleashed:Unlike traditional manufacturing methods, CNC machining isn’t limited by complexity. Transform your intricate designs, featuring curved surfaces, internal structures, and fine details, into reality with exceptional precision. This allows designers to push boundaries and explore innovative concepts with minimal limitations.

- Rapid Prototyping for Faster Innovation:Time is of the essence in today’s competitive landscape. The efficient nature of CNC machining enables rapid prototyping, allowing you to receive prototypes quickly. This translates to faster design iterations, shorter development cycles, and a swifter time-to-market for your product.

- Cost-Effective Prototyping Solutions:CNC machining shines in small-batch production runs, making it an ideal choice for cost-effective prototyping. This keeps your development stage expenses under control without compromising quality.

Benefits Specific to Procurement Personnel:

- Reliable Prototypes, Reduced Costs:The high precision and repeatability of CNC machined aluminum prototypes translate to fewer rework needs and lower overall project costs.

- Faster Delivery Times, Stronger Market Position:The efficient nature of CNC machining ensures quicker prototype turnaround times. This translates to faster product launches and a stronger competitive edge in the market.

Benefits Specific to Designers:

- Transforming Vision into Reality:CNC machining grants designers the freedom to explore complex features and intricate details, bringing their design concepts to life with exceptional accuracy.

- Rapid Prototyping for Faster Design Iteration:The ability to receive prototypes quickly allows for swift design adjustments and testing, accelerating the design refinement process.

Beyond Prototyping: The Performance Benefits of CNC Machined Aluminum

Aluminum’s inherent properties – lightweight, corrosion-resistant, and thermally/electrically conductive – make it a versatile material for various applications. CNC machining unlocks these advantages even further:

- Weight Reduction:In industries like aerospace and automotive, where every ounce counts, CNC machining allows for precise material removal, optimizing weight without sacrificing part strength.

- Thermal Management:CNC machining can create intricate channels within a prototype, facilitating efficient heat dissipation in electronics or medical equipment.

Ready to Experience the Power of CNC Machined Aluminum Prototypes?

Contact us today to discuss your project requirements and get a free quote. Let’s collaborate to transform your innovative ideas into flawless prototypes, accelerating your product development journey.

Español

Español