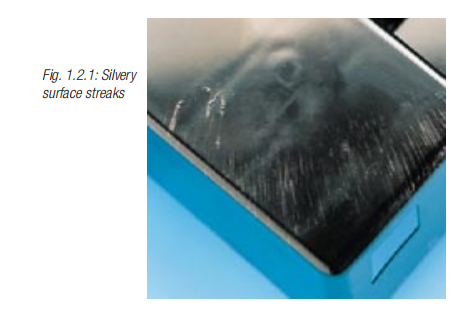

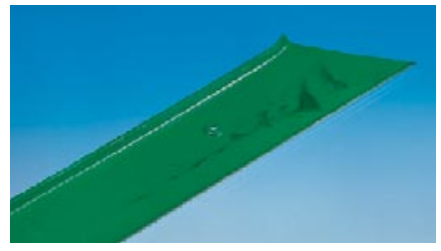

Silver streaks are a very common phenomenon appearing on the surface of plastic injection molded products. They are shining line shaped patterns usually caused by moisture, but can also be caused by high filling rates and poor vents which can cause entrapping of gas either from the environment, mold water leaks, etc. These can be considered external appearance quality defects in exterior parts of consumer electrical products, automobiles, motorcycles, etc. The most commonly seen streaks are shown as below.

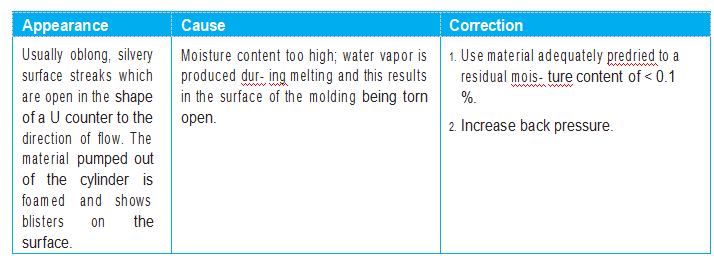

Moisture streaks/splay marks

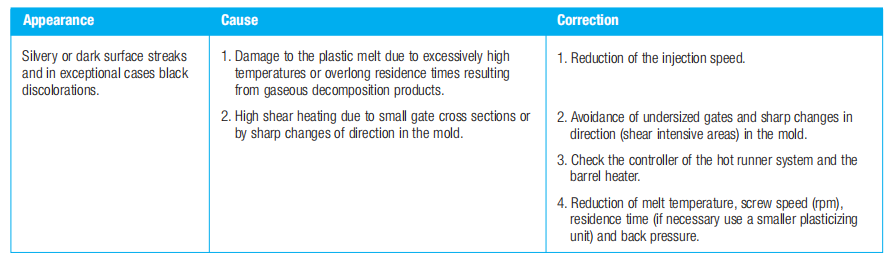

Burning streaks/silver streaks

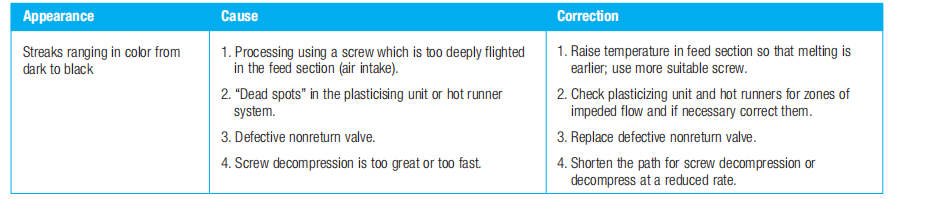

Dark streaks

Color streaks

The cause for the formation of streaks can be deter-mined in many defective injection products only after costly investigations,especially as the appearance of burning and moisture streaks is similar.Extensive knowledge of the plastic,the mold design and the plastic injection molding processing are indispensable for overcoming the problem.Before launching expen-sive and time-consuming investigations the following points should be checked in the sequence given and if necessary optimized:

- Melt temperature

- Injection speed

- Residence time in the cylinder

- Back pressure

- Moisture content of granules

- Mold venting

- Cleaning of the plasticising unit

- Screw recovery speed HS Mold is a leading China custom injection molder and manufacturer of plastic components and assemblies. We have accumulated rich exprience through vast fullfillment of practical injection molding projects. For any other commonly injection molding defects, click injection molding process

Español

Español