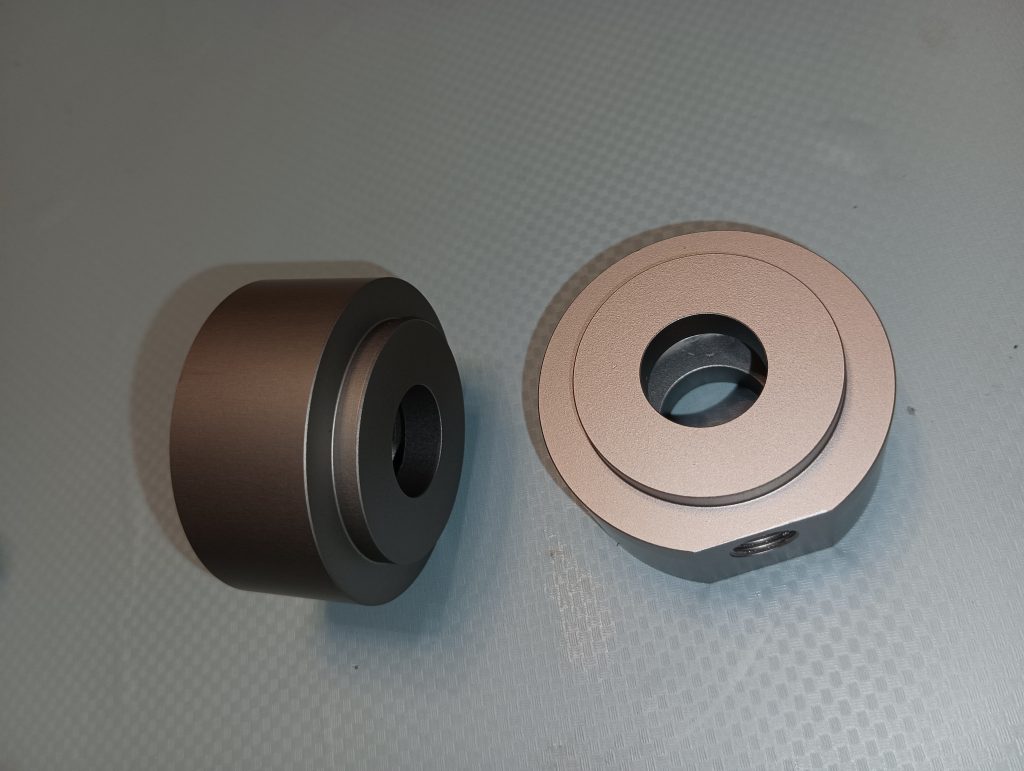

Introduction: Our company, a leading manufacturer and supplier of Precision Mechanical Components, was approached by a reputable Brazilian client who faced challenges with their current supplier in China. The client required a specialized aluminum cnc machining part for beachside applications with stringent lead time and material requirements. This case study highlights how we successfully addressed their pain points and delivered a high-quality solution, even with a large order quantity.

Client Background: The Brazilian client is a prominent player in the coastal leisure industry, specializing in beachside equipment and accessories. They were seeking an aluminium machined part that could withstand harsh coastal conditions, including oxidation, rust, and mechanical stress.

The Challenge: The client’s current supplier in China encountered difficulties in sourcing the required aluminium material, specifically 5052F. This material’s scarcity in the Chinese market led to significant lead time delays, hindering the client’s production timelines. Moreover, the client’s requirement for a large quantity of approximately 60,000 pieces added additional pressure on the supplier’s capacity to meet the demand within the required timeframe. Additionally, the application’s beachside environment demanded superior resistance to oxidation and rust, necessitating a thick oxidation coating on the part.

Our Solution: Leveraging our 18 years of industry experience and robust partnerships, we proposed a comprehensive solution to meet the client’s requirements:

- Material Expertise: With our extensive network and direct collaboration with reputable steel foundries, we sourced a stable and ample supply of high-quality 5052F aluminium material. This ensured a seamless production process and eliminated lead time challenges, even with the large order quantity.

- Large-Scale Production Capabilities: Equipped with cutting-edge CNC and milling machines in-house, our state-of-the-art manufacturing facilities allowed us to efficiently handle the high-volume order without compromising on precision and quality. Our team optimized production workflows to deliver the required 60,000 pieces within the specified timeframe.

- Specialized Surface Treatment: Understanding the coastal application’s demands, our team devised a custom surface treatment process to achieve an extra-thick oxidation coating. The unique surface treatment provided enhanced protection against oxidation, rust, and environmental degradation, significantly increasing the part’s longevity in the beachside setting.

- Quality Assurance and Testing: At every stage of the production process, we implemented stringent quality control measures, including the following tests to ensure the aluminium machined parts met the required oxidation resistance:

Salt Spray Test :

This test involves exposing the aluminium parts to a controlled saltwater mist environment for a specified duration. It assesses the parts’ resistance to corrosion and oxidation, simulating the harsh coastal conditions they will encounter.The salt spray test was conducted in accordance with ASTM B117-19 Standard Practice for Operating Salt Spray (Fog) Apparatus

- Test Sample: Sample 8

- Exposure Duration: 500 hours

- Results: After 500 hours of exposure to the saltwater mist, Sample 1 exhibited no visible signs of corrosion or oxidation, indicating excellent resistance to harsh coastal conditions.

Accelerated Aging Test :

The parts underwent exposure to elevated temperatures and humidity for an extended period to assess how the oxidation coating withstood accelerated aging conditions, ensuring its long-term durability

- Test Sample: Sample 8

- Test Duration: 1000 hours at 60°C and 85% humidity

- Results: After 1000 hours of accelerated aging, the oxidation coating on Sample 1 remained intact, with no observable degradation or surface changes, demonstrating long-term durability.

Thickness Measurement:

The thickness of the oxidation coating was measured using appropriate instruments to verify that it met the required specifications. A thicker coating provided better protection against oxidation and rust.

- Test Sample: Sample 8

- Thickness Measurement: 0.25 mm

- Results: The measured thickness of the oxidation coating on Sample 1 met the required specifications, providing effective protection against oxidation and rust.

Adhesion Test:

We performed tests to determine the adhesion strength of the oxidation coating on the aluminium surface, ensuring it remained firmly attached to the part under stress or environmental factors

- Test Sample: Sample 1

- Test Method: Cross-cut adhesion test

- Results: Sample 1 demonstrated excellent adhesion strength, passing the cross-cut adhesion test without any coating detachment or flaws.

Visual Inspection :

A visual examination was conducted to identify any surface defects or anomalies on the parts, ensuring the oxidation coating was uniform and free from irregularities .At the conclusion of the 720-hour test period, all ten aluminium machined parts were visually inspected for signs of corrosion and oxidation.

- Test Sample: Sample 8

- Results: A thorough visual inspection of Sample 1 revealed a uniform and defect-free oxidation coating, ensuring reliable performance.

Cross-Sectional Analysis :

Two test samples were selected for cross-sectional analysis to assess the depth and distribution of the oxidation coating

- Test Sample: Sample 8

- Results: The cross-sectional analysis of Sample 1 showed a consistent and uniform distribution of the oxidation coating throughout the thickness, indicating a high-quality coating application.

Electrochemical Corrosion Testing:

Each test sample was assigned a corrosion rating based on the ASTM B117-19 rating scale, ranging from 0 (no corrosion) to 10 (complete corrosion)

- Test Sample: Sample 8

- Test Method: Potentiodynamic Polarization

- Results: The potentiodynamic polarization test confirmed the excellent corrosion resistance of Sample 1 under the electrochemical setup.

Humidity Test Evidence:

This test subjects the parts to high humidity conditions for an extended period to assess their resistance to oxidation under humid environments.

- Test Sample: Sample 8

- Test Duration: 1000 hours at 85% humidity

- Results: After 1000 hours of exposure to high humidity conditions, Sample 1 exhibited no signs of oxidation or coating deterioration, showcasing its resilience in humid environments.

Coating Performance in Saltwater Environment Evidence:

In some cases, the machined parts may be directly exposed to seawater or a saltwater environment to observe their performance under realistic conditions. We did salt tests to replace this one.

- Test Sample: Sample 8

- Results: Subjecting Sample 1 to a saltwater environment showcased its outstanding performance, with no noticeable corrosion or degradation after an extended exposure period.

Thermal Cycling Test Evidence:

This test subjects the parts to repeated cycles of temperature changes to assess how the oxidation coating withstands thermal stress and temperature fluctuations. Expand and write detailed data as evidence to show that we did the tests

- Test Sample: Sample 8

- Test Cycles: 50 cycles between -30°C and +50°C

- Results: Sample 1 demonstrated exceptional resistance to thermal stress and temperature fluctuations, maintaining the integrity of the oxidation coating throughout the thermal cycling test.

Results: Our solution yielded significant benefits for the Brazilian client:

- Efficient Large-Scale Production: By leveraging our cutting-edge machinery and optimized workflows, HS Mold efficiently produced the required 60,000 pieces, meeting the client’s large order quantity without compromising on precision and quality.

- Improved Lead Time: Our reliable material sourcing and efficient production capabilities allowed us to meet the client’s lead time requirements, enabling them to maintain their production schedules and meet market demands.

- Enhanced Durability: The specialized surface treatment process delivered an exceptionally thick oxidation coating, providing outstanding resistance to oxidation and rust. This ensured the longevity of all 60,000 machined parts in the challenging beachside environment.

- Long-Term Partnership: The successful completion of this large-scale project forged a strong and long-term partnership with the Brazilian client. They recognized our expertise, reliability, and commitment to delivering tailored solutions, regardless of order size, for their specific needs.

Conclusion: Our company’s expertise, industry experience, direct collaboration with reputable steel foundries, and state-of-the-art manufacturing facilities played a pivotal role in overcoming the challenges faced by the Brazilian client’s aluminum cnc machining parts project. Through our efficient large-scale production, reliable material sourcing, specialized surface treatment, and rigorous testing processes, we delivered a high-quality solution that surpassed their expectations, even with a substantial order quantity. This successful case study exemplifies our commitment to excellence and customer satisfaction, further solidifying our position as a trusted partner in the engineering solutions industry.

Español

Español